|

| |

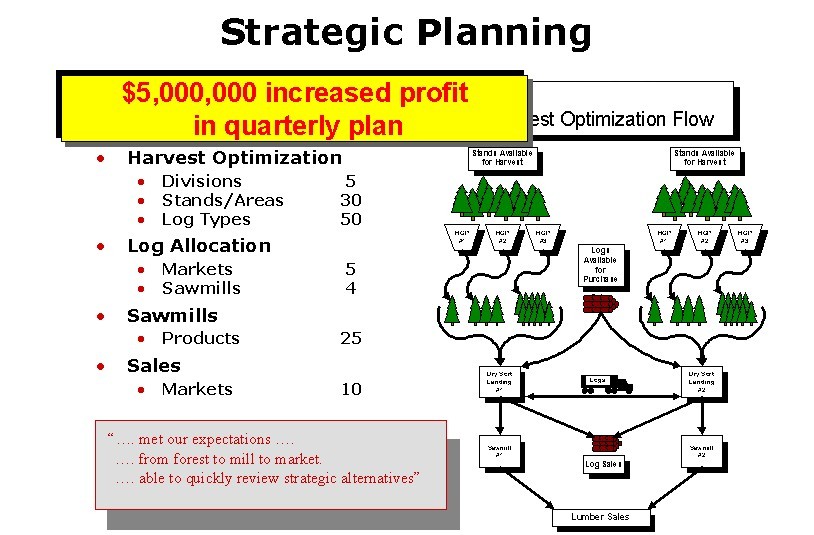

A harvest region with more than 300 stands of timber, 3 external

sales destinations and 12 internal mills was modeled. The mills

were modeled by a return-to-log computation for each of the 15 log

types modeled, producing a re-allocation of the timber destinations

for 6% of the timber, and increasing profits by 2% of gross revenue.

Key Benefits

| Timber is allocated to the highest bidder, net of freight and other

quantifiable expenses. |

| Timber is shipped ONLY to locations which can use it -- no trans-shipping

is required to cover errors |

| Expenses are reduced. |

| Stands are harvested most efficiently. |

| Shortfalls are specifically identified so that spot purchases can be

planned ahead of time to fill the gaps, or additional harvesting scheduled. |

Return on Investment

The model was limited (by freight availability) to increasing ton-miles by

no more than 5%. Within that constraint, 9% of the logs were shifted

from their default destinations, with a gain of 3% in revenue for the

harvest (net of added freight expense).

|